Railroad Track Pans

ULTRATECH RAILROAD SPILL CONTAINMENT - RAILCAR TRACK PANS

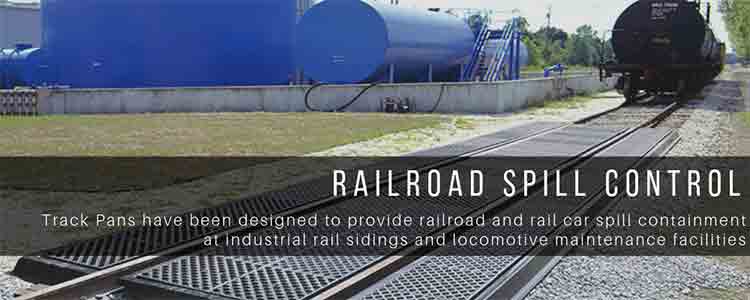

Ultra Track Pans for railcar spill containment have been designed to provide railroad & railcar spill containment at industrial rail sidings and locomotive maintenance facilities. They are also useful to prevent costly cleanup and regulatory fines. Railroad spill containment pans are available in virtually any length, Ultra Track Pans may be used to collect small spills and leaks OR to capture and channel off to provide significant railcar spill containment caused by defective equipment or a major overflow.

25 years in business, & over 2500+ FIVE-★★★★★ Star Third Party Client Reviews, allows you to confidently Buy @ IPI your Railcar Track Pan and Systems.

The rugged polyethylene spill containment products are designed to withstand harsh chemicals and are designed to function in temperatures ranging from -40°F to +140°F. The polyethylene gaskets keep spills from falling between rails and pans. Trucks and other vehicles can drive over the Railcar Track Pans with grates in place.

Optional track pan covers keep rain water out of the pan, providing effective stormwater management. The cover is made of polyethylene and can be left in place until the railcar arrives to be off-loaded or loaded. This lightweight cover mechanically locks into the polyethylene decking and will not blow off in windy conditions.

Ultra-Track Pans are available in two models, one with a cover and one without. They are low maintenance. The Railroad spill pan has a polyethylene resin with a UV inhibitor to resist sun and corrosion damage. All top surfaces are designed to resist slips and falls. These railcar spill containment pans also have a long work life, they will last 20-30 years.

• Prevent costly Rail Road cleanups and regulatory fines!

• UltraTech's polyethylene gaskets keep spills from falling between the rails and pans.

• Can be used for a range of purposes, from Railcar spill kits to dock boxes, these units can store whatever you need.

Call us toll free at 1-800-474-7294

Our volume discounts will save you money on Railcar spill containment! We provide expert service and value pricing, but if you find an advertised price lower we will of course be happy to beat it. 25 years in business, wiith over 2500 plus FIVE-★★★★★ Star Third Party Reviews, allows you to confidently Buy @ IPI.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Frequently Asked Questions (FAQ) about Track Pans

1. How long will Ultra-Track Pans last in the field?

Under normal working conditions, the TrackPans should last from 20 to 30 years in the field. Due to rugged conditions expected at rail sidings, the TrackPans are molded in nearly twice the thickness of standard containment products manufactured by UltraTech. The black color, combined with an ultraviolet (UV) ray inhibitor added to the polyethylene resin, helps protect the TrackPans from harmful effects of the sun.

2. How much containment capacity do the TrackPans have?

Without Grates, each Center TrackPan holds 30 gallons and each Side TrackPan holds 25 gallons. Each TrackPan Grate displaces 6 gallons of fluid. Therefore, each Center TrackPan with Grates holds 18 gallons and each Side TrackPan with Grates holds 19 gallons.

Ultra-TrackPans are connected together with bulkhead fittings. One (1) bulkhead fitting is used to connect each Side TrackPan "end to end" and two (2) bulkhead fittings are used to connect each Center TrackPan "end to end". The patented bulkhead fitting design allows spilled fluids to travel from one TrackPan to the next, thereby increasing capacity as the spill travels over the length of the TrackPan System.

3. How much maintenance is required to use the TrackPans correctly?

The TrackPans are virtually maintenance-free. Visual inspection of the sealing gaskets located between the rails and Pans should take place every six (6) months. If TrackPan Covers are used, the sealing gasket located inside each Center Cover "spout" should also be visually inspected every six (6) months. In addition, if Covers are used, leaves and other debris that may inhibit stormwater flow through the "stormwater ports" (located in the Center TrackPan Stormwater Feature) should be removed when present.

4. What are the TrackPan sealing gaskets made of?

The gaskets that seal between the Pans and tracks are closed-cell polyethylene foam. The closed-cell material will not soak up any fluid.

5. What are the TrackPans, Grates, Covers and bulkhead fittings made of?

All of these items are made of polyethylene. Coupled with the polyethylene track gaskets, the TrackPan product line offers consistent chemical compatibility. Note: Standard gaskets for the bulkhead fittings are EPDM. Other materials are available if necessary.

6. What benefits do the TrackPan Covers provide?

Most importantly, the TrackPan Covers keep rainwater out of the Pans. This benefit helps facilities meet various Stormwater Management Requirements. If the TrackPan System uses "below grade" piping that leads to an oil/water separator or other treatment process, the Covers eliminate the costs associated with treating clean stormwater. TrackPan Covers also keep debris out of the Pans.

7. How do the Grates and TrackPan Covers function together?

Center and Side Covers have molded-in "thumbs" that protrude from their undersides. These "thumbs" friction fit into the grates, allowing the Covers to stay in place in windy conditions. The Grates also provide structural support for the Covers, allowing foot traffic on top of the covers.

8. How chemically-resistant are the TrackPans?

The all-polyethylene Ultra-TrackPans offer excellent chemical resistance for a broad range of acids, caustics, corrosives, solvent, oils, diesel fuel, etc. UltraTech's engineering staff is available to review specific chemicals upon request.

9. What are the most popular Ultra-TrackPan sizes?

The 9-foot and 60-foot Ultra-TrackPan Systems are the most popular. The 9-foot System helps facilities capture "nuisance spills", while the 60-foot System spans the entire length of a locomotive or typical railcar.

Due to widely varying customer needs, the modular TrackPans have been provided in many different lengths and can be provided in any multiple of 4½ feet. Note: If an overall length is required that is not a multiple of 4½ feet, TrackPans can be easily fabricated by UltraTech to meet specific needs.

10. Railcar loading/unloading areas tend to experience high foot traffic. How do the Ultra-TrackPans address OSHA "slip and fall" issues?

All top surfaces of the major TrackPan components feature a slip-resistant design. Grates and Covers have a raised, molded-in texture that is very similar to a diamond plate design. The inner surface of all Center and Side TrackPans has a surface that is similar to 80 grit sandpaper.

11. What is the working temperature range for Ultra-TrackPans?

-40° F up to + 140° F

12. Does "wind chill" have any effect on the TrackPans?

No effect.

13. What equipment and tools are required to install Ultra-TrackPans?

Metal rake, shovel, sledgehammer, two 12" bar clamps, two pieces of wood 1" x 4" x 48", two "slip sheets" approx. 10" x 60", and a utility knife are typically required.

No heavy equipment required.

14. Can TrackPan Covers be removed AFTER a railcar has been positioned over top of a TrackPan System?

Yes. Side Covers and Center Covers can be removed after the railcar is in place.

15. Do I need to order gaskets and bulkhead fittings separately when purchasing Ultra-TrackPans?

No. Gaskets and bulkhead fittings are standard components and are packaged inside each TrackPan shipping container. Note: If planning to install below grade piping, 3" diameter bulkhead fittings to connect to piping must be ordered separate

16. How are the TrackPans shipped?

Each TrackPan is boxed separately to assure they are protected properly during shipment. The modular units stack neatly on wooden shipping pallets via LTL or full truckload shipments, depending on the size of order.

17. Have the Ultra-TrackPans been designed to be connected to "below grade" piping to allow large spills to be channeled to oil/water separators, holding tanks, etc.?

Yes. Center Pans and Side Pans have molded-in recesses at their low points. The recesses are shaped like large "hockey pucks" and can easily be drilled out for 3" diameter polyethylene bulkhead fittings.

18. Why are there multiple pipe recesses molded into each TrackPan?

The location and spacing of railroad ties along a set of rails is not entirely predictable. We have provided multiple pipe recesses to guarantee that at least one recess can be used for piping without disturbing any ties.

19. Do I have to connect the Ultra-TrackPans to below grade piping?

No. The pipe recesses give you the option to do so if desired. Many users are concerned only with capturing small spills and leaks and do not have the desire or need to pipe below grade.

20. Will UltraTech provide assistance to help determine below grade piping specifications and design?

Yes. As potential Track Pan projects move forward, our engineering staff will provide design assistance upon request.

21. Can Ultra-TrackPans be installed on a curved track?

Yes. The modular design of the TrackPans allows them to follow along a curved track up to 12 degrees without any customization. Please contact UltraTech for technical assistance on any track with a curve greater than 12 degrees.

22. Can Ultra-TrackPans be installed on any tracks, regardless of rail weight?

(Note: Rail weight is defined as the number of pounds per yard of rail length.)

Ultra-TrackPans have been successfully installed on rails as light as 65 lb. All rails greater than 65 lb. work very well with Ultra-TrackPans. Rails that are less than 65 lbs. are not feasible as the rails are too short to allow proper clearance.

23. Upon placing an order for Ultra-TrackPans, does UltraTech need to know the rail weight of the track?

Yes. UltraTech will provide a drawing that details a cutaway of a standard rail and tie plate. We will request that two (2) specified dimensions be provided to us. These dimensions determine the correct gasket design that the installation will require.

24. Does UltraTech offer turnkey installation service for the Ultra-TrackPans?

Yes. UltraTech has personnel qualified to install TrackPans, with or without below grade piping. UltraTech personnel will travel to installation sites on a contract basis.

25. What length TrackPan System is required to handle a typical railcar or locomotive?

• Railroad tanker cars typically range from 35 - 60 feet. Each Ultra-TrackPan is 53.5" (4½ nominal feet) long and can be configured to virtually any length desired.

• Locomotives typically require a 60-foot TrackPan System.

26. How many TrackPans make up a 9-foot System? 40-foot System? 60-foot System?

(Note: The following answers to these questions assume that each TrackPan System includes Center TrackPans and Side TrackPans on both sides of the tracks.)

• 9-foot Systems: two (2) Center Pans, four (4) Side Pans

• 40-foot Systems: nine (9) Center Pans, eighteen (18) Side Pans

• 60-foot Systems: fourteen (14) Center Pans, twenty-eight (28) Side Pans

27. Can vehicles be driven over the TrackPans?

Yes, provided the following:

• TrackPan Grates are in place in each pan.

• Adequate support (i.e. compacted soil) is provided under each Pan.

• If side Pans are installed, concrete must be poured to "ramp up" to the outer sidewalls of the Side Pans.

Note: Vehicle weight limitation of the TrackPans is dependent on the strength of the bedding material under the Pans. UltraTech engineers are available to provide guidance in specifying bedding material, etc.

28. Can vehicles drive over the Spill Containment TrackPans WITH Covers in place?

UltraTech does not recommend driving over the TrackPans with Covers in place. We recommend removing the Covers before driving vehicles over the TrackPans.

29. When clean stormwater (rain) falls on top of TrackPans with Covers in place, where does the water go?

Side TrackPans - when installed, the Side Pans are positioned at a slight angle, sloping away from the tracks. Rain that falls on top of the Side Pan Covers, runs off of the outside of the Covers, just as rain runs off the outside edge of a rooftop.

Center TrackPans - because Center TrackPans have a rail located on both sides, it is not possible to channel rain off to either side. UltraTech has patented a means to channel clean stormwater onto the ballast beneath the Center TrackPans, keeping rain out of the Center TrackPans and your railcar spill containment intact.

Discover the IPI difference where you will always find tremendous value, incredible selection and unequaled service with every product we sell. Please call today to speak with a representative about track pans @ USA Office: 800-474-7294 or International: 941-377-8610.

There are no products listed under this category.